At MeowAI, we believe that every communication is the beginning of cooperation and innovation. Whether you are seeking customized industrial software solutions or professional technical support in the fields of data analysis, data security, and artificial intelligence, we are happy to listen and provide the best help. Please contact us through the following methods and start our cooperation journey.

Contact method

iSchedule

iSchedule developed by Shanghai Miaomiao Tour Intelligent Technology Co., Ltd. is an intelligent scheduling software guided by the Theory of Constraints. Its characteristics include dynamic scheduling, minimum inventory, minimum work in process and ensuring full-load operation of bottlenecks. It can interact with systems such as ERP, MES and WMS, and can receive order data, work order plans, obtain shipping lists and completion and inventory status. It has modules such as order management, BOM management, production line management, process management, production calendar, MRP calculation and generation of weekly plans, meeting the needs of different enterprises and providing efficient and flexible production scheduling solutions for enterprises.

Product Information

- Product NameiSchedule

- Technology StackVue3 +.Net Core

- Industry CategoryDiscrete manufacturing

Our advantages

In today's complex manufacturing environment, our APS brings a brand new change to enterprises. It provides a comprehensive solution that can deal with various complex challenges faced by enterprises. iSchedule is committed to optimizing production scheduling, improving efficiency and reducing costs. With its advanced functions and characteristics, it gives enterprises a powerful force to maintain a leading position in the highly competitive market.

- Advanced theory guidance

- Strong interaction ability

- High degree of customization and flexibility

- Professional team support

- Dynamic and efficient scheduling

- Cost control advantage

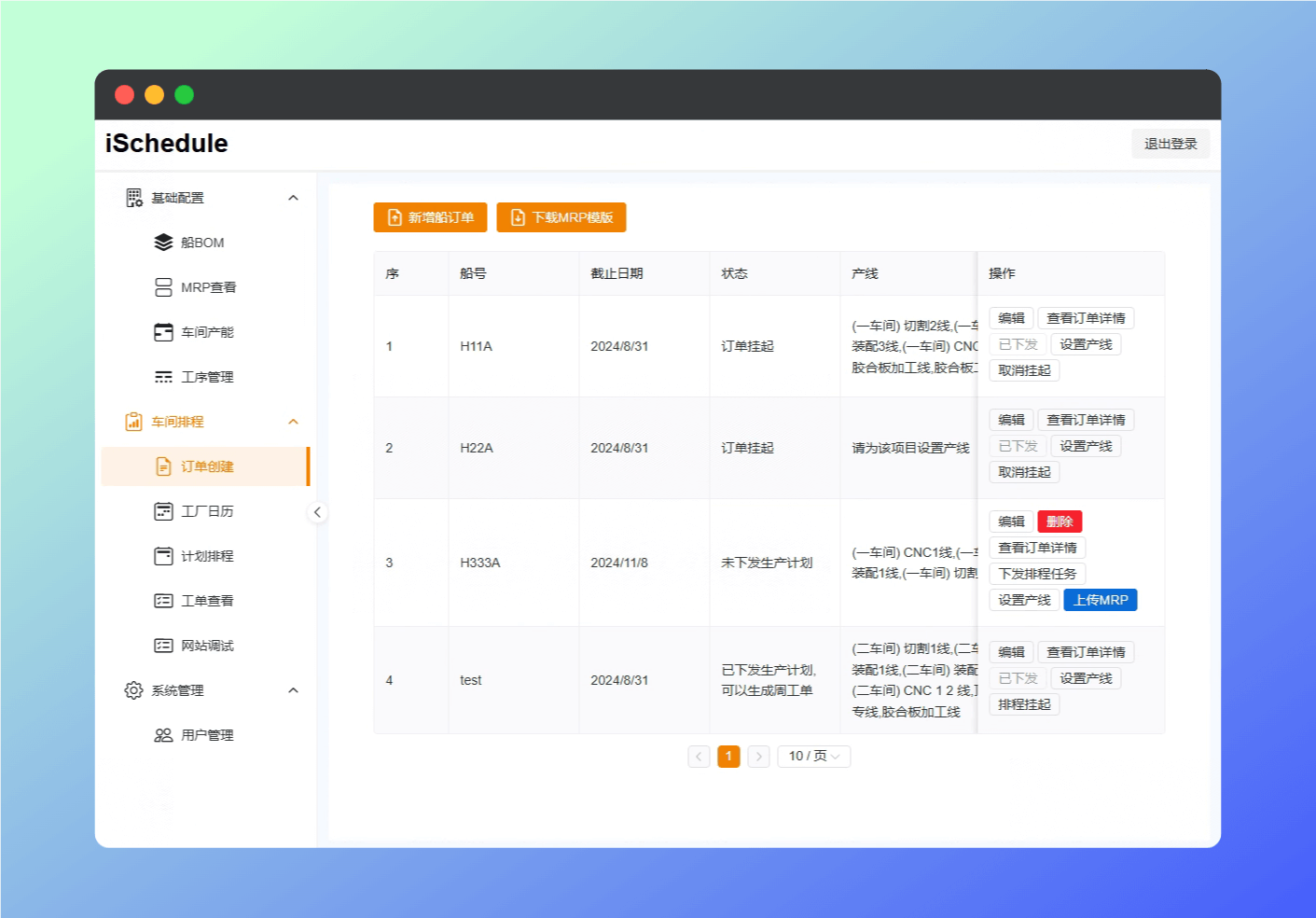

Order management function

Support operations such as adding, deleting, modifying and querying orders. Provide two ways to obtain orders. Orders can be pulled/pushed from ERP, and users can also manually add and import orders. For shipping lists, they can be customized according to the actual situation of customers and can be obtained from the ERP system or imported from Excel files.

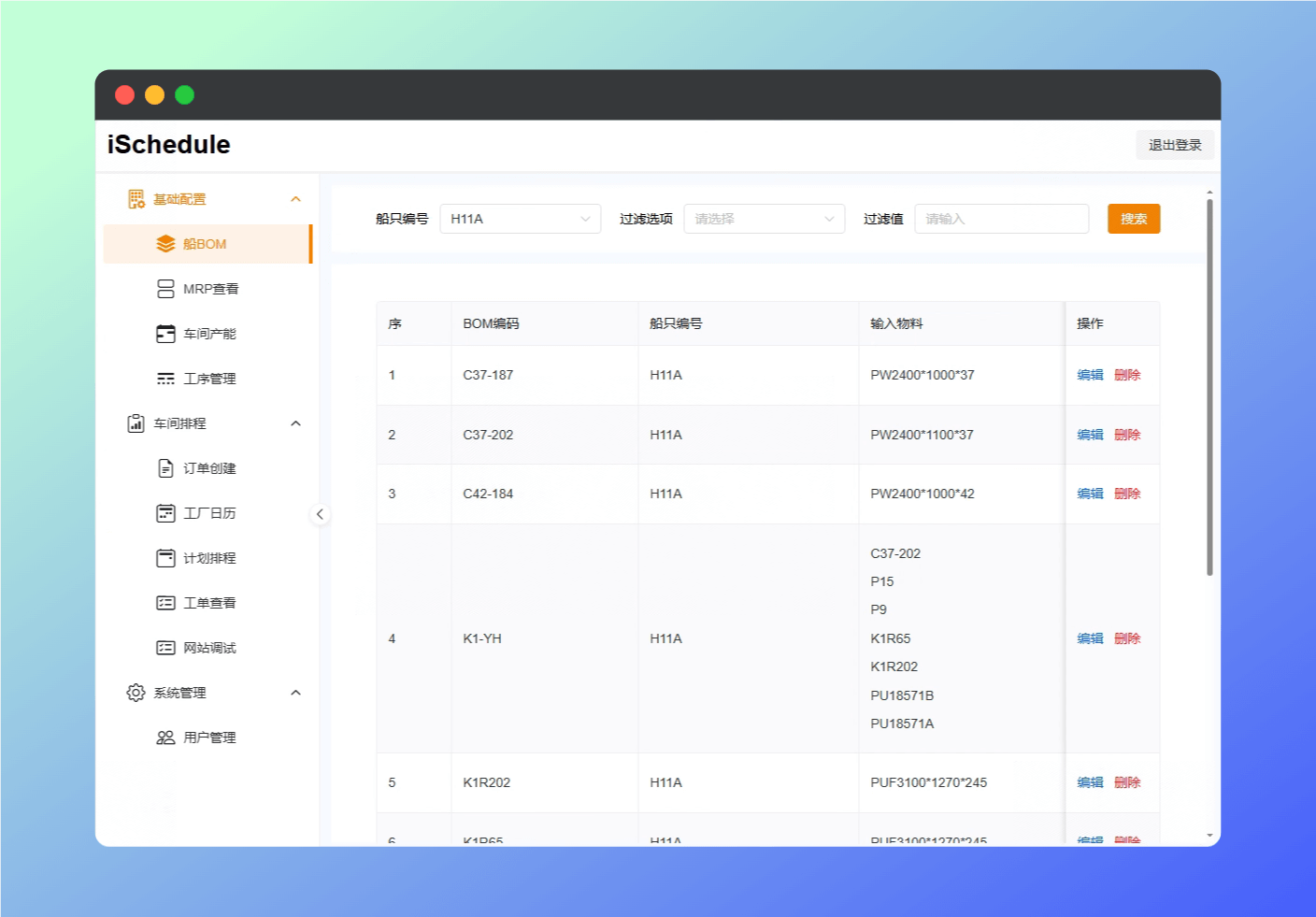

BOM management function

Provide two ways to import BOM. BOM information can be pulled from other systems (such as MES, PDM, etc.), or obtained from Excel files manually uploaded by the customer's process management department.

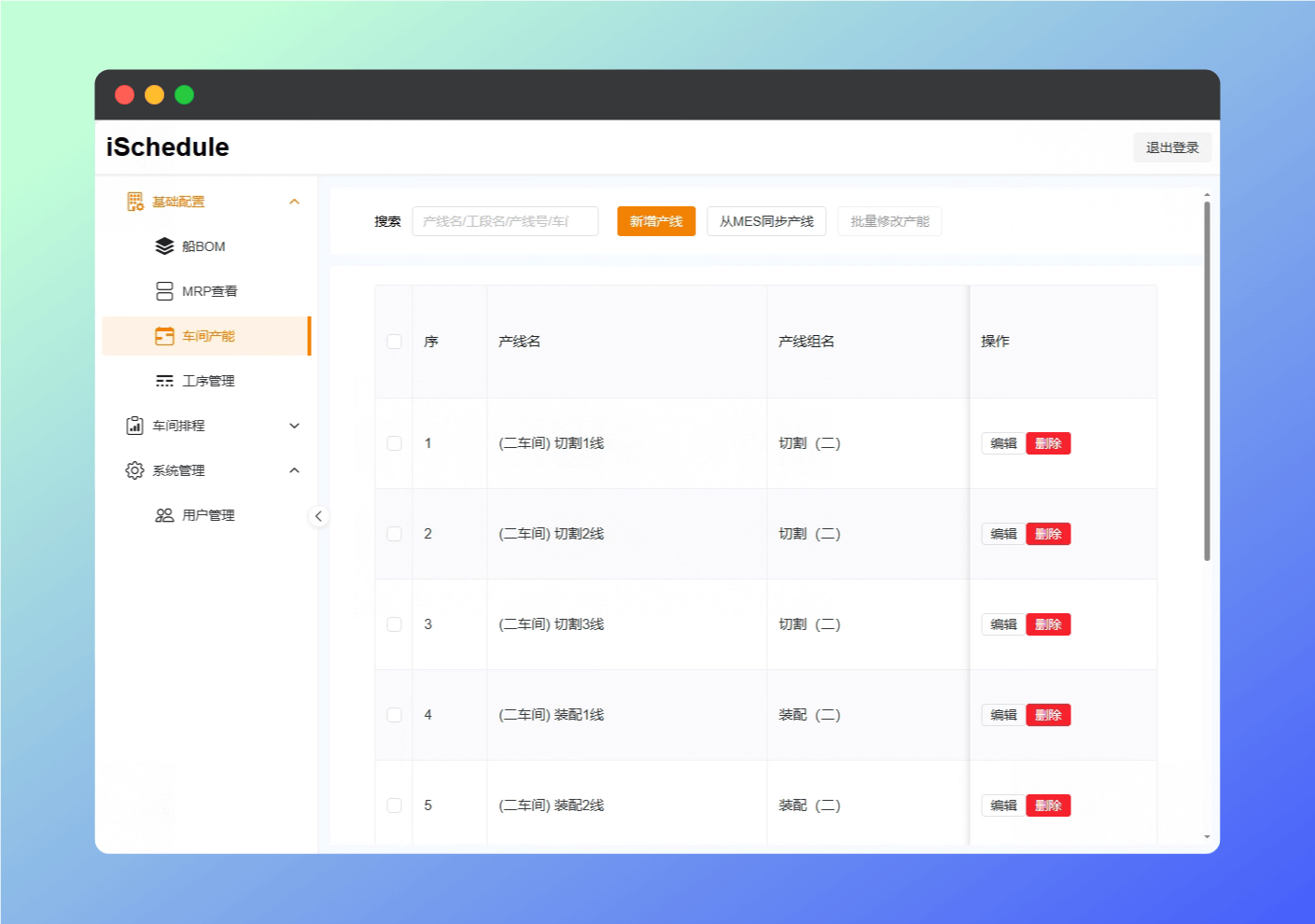

Production line management function

Users can add, delete, modify and query production lines and modify capacity data. According to the granularity of data provided by customers, the management method can be flexibly adjusted. It can be either traditional production line management or management of processing time and setup time according to needs.

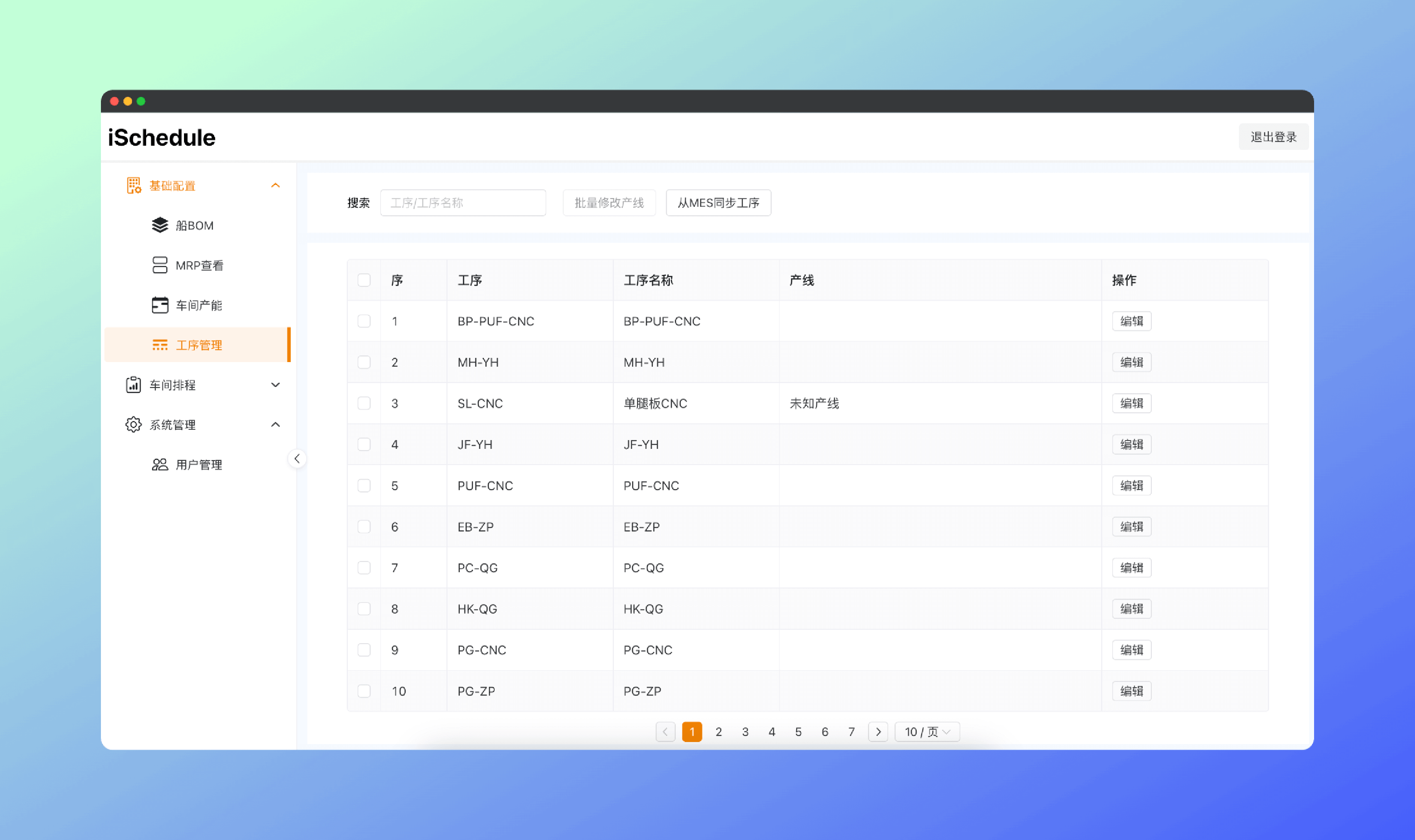

Process management function

The process list supports operations such as adding, deleting, modifying and querying, and supports selecting the corresponding production line for each process, providing an accurate basis for subsequent scheduling calculations.

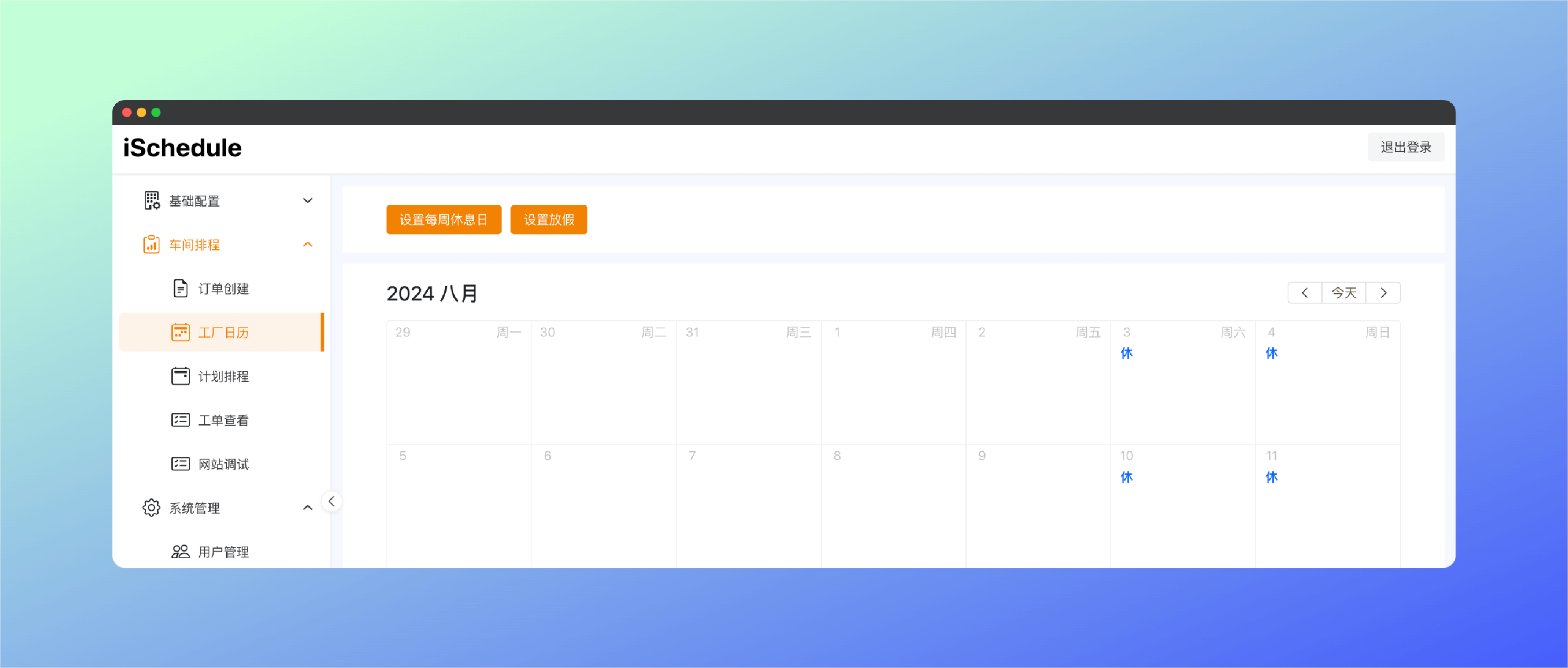

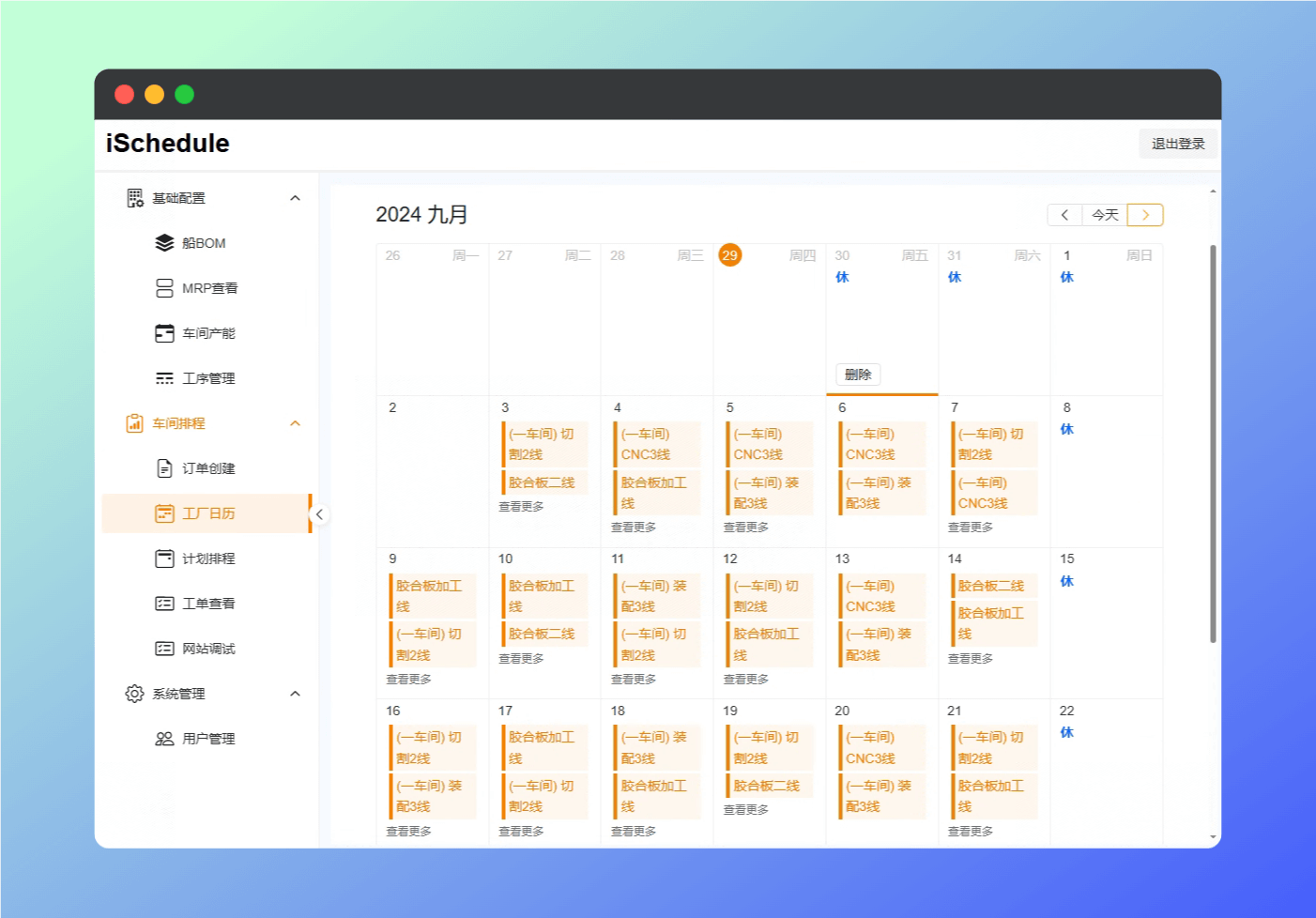

Production calendar function

Support setting regular rest days and holiday arrangements every week, and also support setting up compensatory leave. Subsequent scheduling calculations will skip the dates set as non-working days.

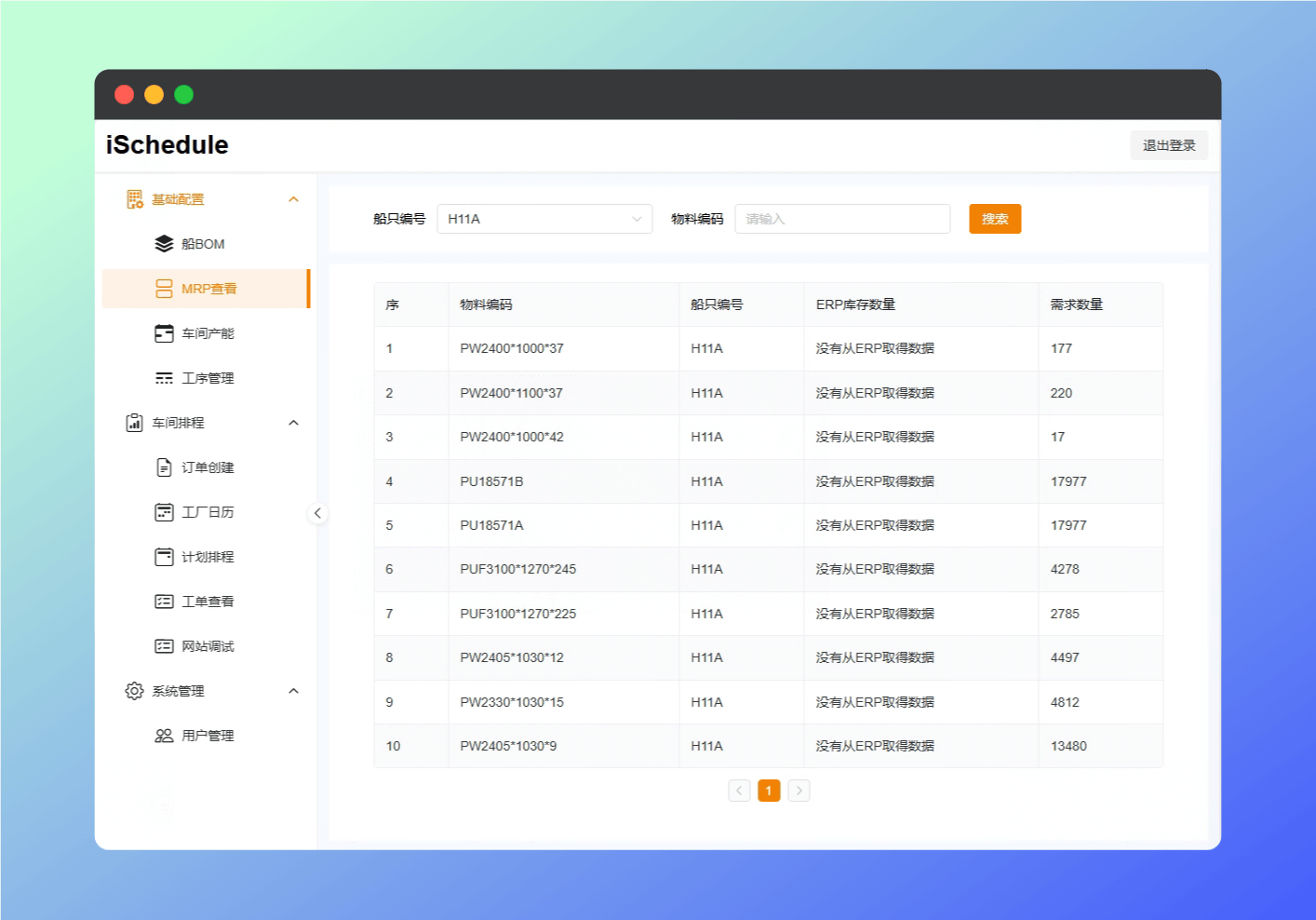

MRP calculation function

For customers without an ERP system or whose ERP system does not include MRP function, custom-provide MRP calculation function and conduct shortage analysis.

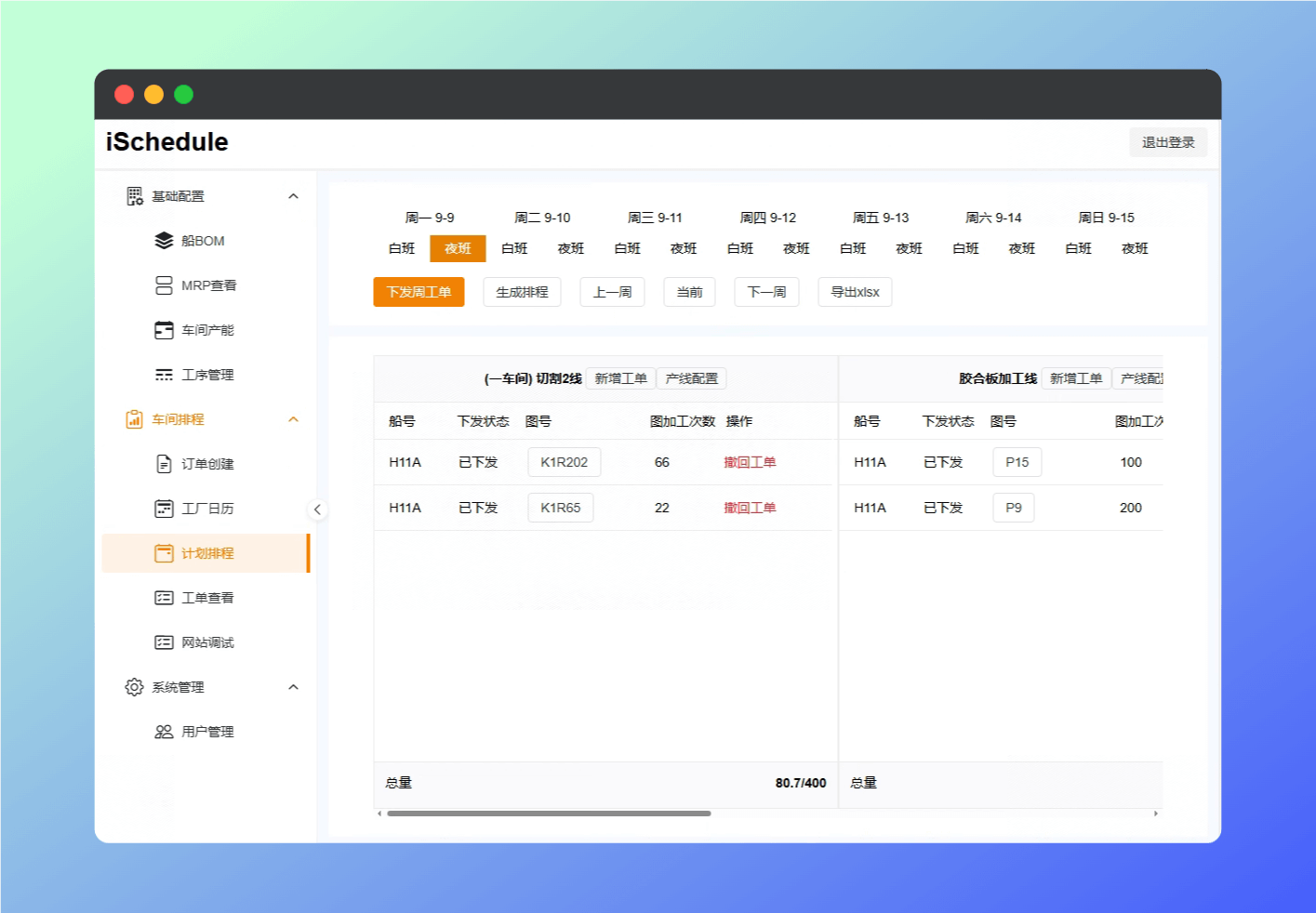

Generate weekly plan function

Based on all basic data, the system generates work orders for a week and indicates which production line each work order is assigned to. If the customer has an MES system online, the generated work orders can be pushed to the MES system and obtain completion data from the MES system to adjust subsequent plans.